Has the boiler been cleaned within the lst 2 years?

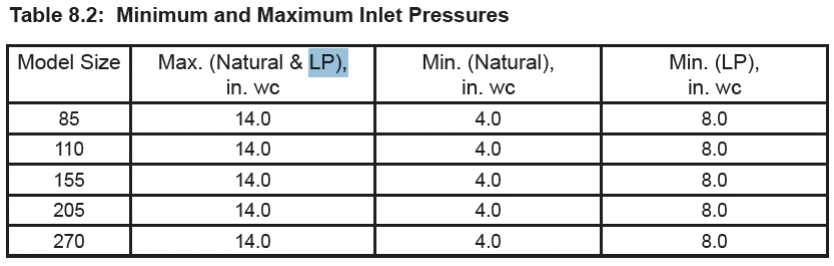

Check static gas pressure and verify the pressure is within spec.

If boiler is not in high fire place the boiler into high fire entering the “Manual Control” button on the control and choose high fire.

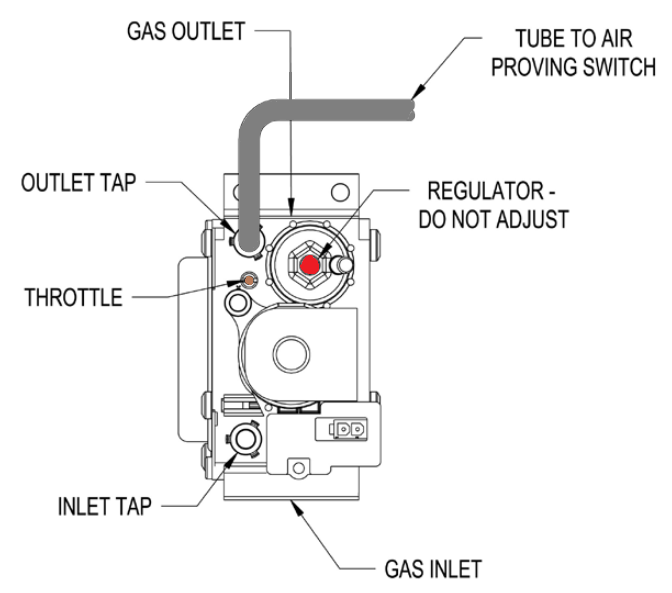

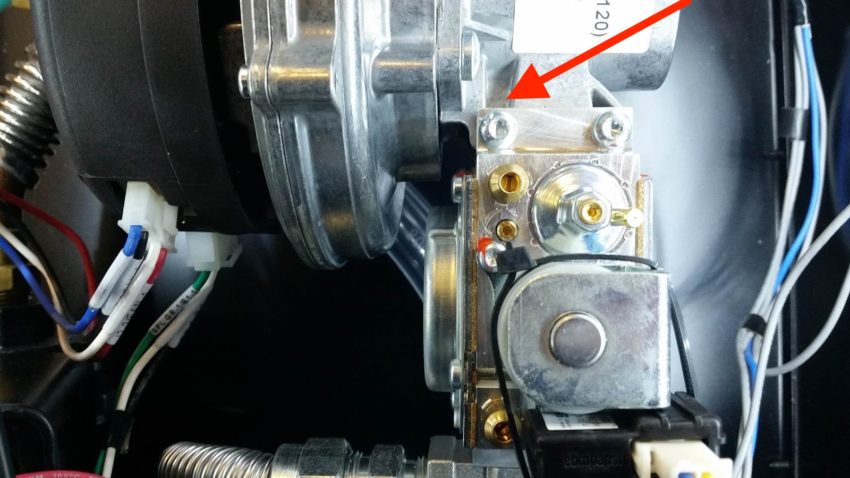

Connect manometer to inlet port on the gas valve

Check incoming gas pressure to the gas valve in high fire. Is pressure within spec?

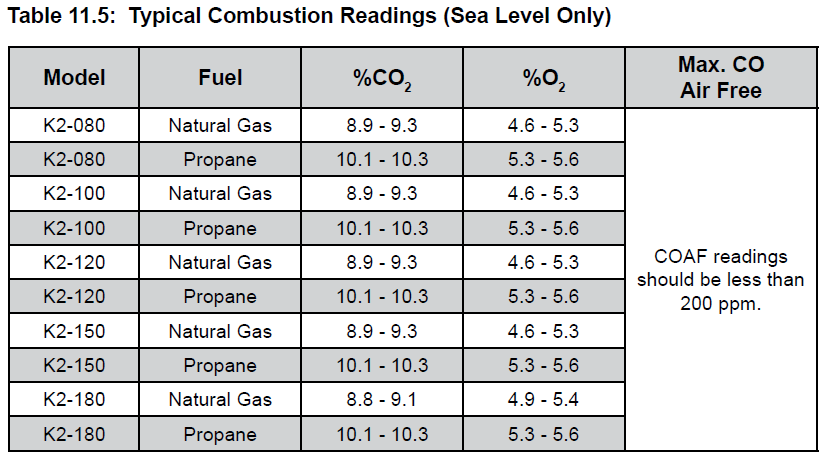

Perform a combustion analysis in high fire. Use the attached charts for O2 and CO spec’s for guidance. Is the burner within spec?

Replace gas valve

Make repairs to maintain proper gas pressures. Possible pipe size or regulator issue. Did the noise resolve?

Disconnect the hose on the sump pressure switch and attach your monometer. Is the reading less than 0.05 or negative?

If the vent termination is easily accesable, use electrical tape and put an “X” over the opening of the vent. Then add a third piece of tape through the center of the “X”. Did the harmonics go away?

Clean boiler

Turn the Throttling screw Counter-clockwise to decrease the O2 and Clockwise to Raise the O2. Do not turn it more than 1/4 turn at a time. Shoot for a midrange adjustment on the O2. If already within spec try going lower with the O2 but stay within range. Does burner get within range?

Try replacing the burner tube. This is not a guanteed fix.

Replace the vent with the 2″ vent Kit from Velocity Boiler Works.

Re-fire the boiler. Did the noise go away?

Go back into the manual modulation screen and change to low fire.

On the gas valve there is an offset adjustment. Using a 2mm Allen wrench you will need to turn an allen screw. Turn it Counter-Clockwise to raise the O2 and Clockwise to lower the O2. This is opposite the Throttle screw. Also use your patience. The fan is moving a very small amount of air. Do not turn more than 1/8 turn at a time. Wait for the combustion analyzer to record the change in O2 and stop changing before you re-adjust the offset. Turning it too much may damage the gas valve. Try to get close to the high fire O2 with this adjustment. When complete turn the boiler off and back on. Did the noise go away?

Call Tech Support

PHNTM – Boilers 80 – 120

PHNTM – Boilers 150 – 180

K2-WT LP and Natural Gas