Press the status button and view the bottom line. We energize the gas valve on “Direct Ignition” Does the gas valve open in “Direct Ignition” You can verify this by having a manometer on the inlet side of the gas valve and see if the gas pressure drops. Another way although not as good of a way is to hold the gas valve. If the pressure drops the valve is opening. Another way, although not as good of a way is to hold the gas valve and feel it opening.

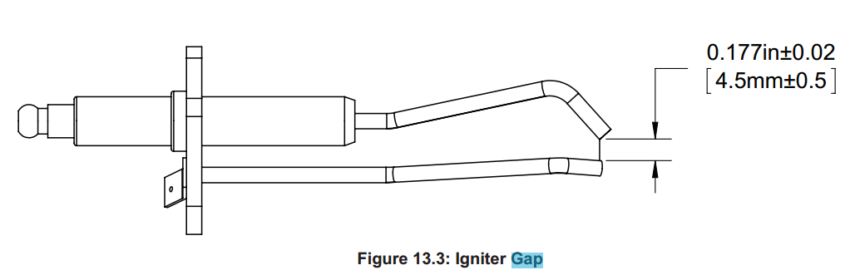

Remove the ignitor and inspect. Is the ignitor distorted or twisted.

Check the gap on the ignitor. Adjust to 0.16″ to 0.19″ (11/64″ +/- 1/64″) or 4 – 5mm. Adjust the ground rod, the one without the porcelain. Start boiler again, did the problem resolve?

With the manometer installed on the inlet side of the gas valve. When the valve opens does the gas pressure drop more than 1-1/2″ w.c.?

Check the regulator/meter and pipe sizing and length. If using CSST I suggest a minimum of 3/4″. Distance may require larger pipe.

When the control sparks does the ignitor spark? You should also hear the spark in the Sage control and at the igniter.

Install a manometer to the inlet pressure tap on the gas valve. Is the incoming gas pressure without the boiler running at or above 4.5″ w.c.?

Did you hear the spark in the control during “pre-ignition” and “Direct ignition“? This would be an intermittent and continuous spark.

Replace the control

Replace the ignition cable

Install a manometer to the inlet pressure tap on the gas valve. Is the incoming gas pressure without the boiler running at or above 11″ w.c. for Phantom.

Cover approximately 1/2 the opening of the air inlet of the fan shroud before the control goes to “Direct Ignition“. If the boiler lights on “direct ignition” keep your hand partially covering the opening for about 30 seconds. Does the boiler light?

Open the “Modulation Setup” menu and try reducing the light-off rate to 3500 rpm’s. Did the boiler light?

Replace Flame Sensor. A normal reading is 4 – 25 dependent on firing rate.

Keeping your hand on the air intake opening, check gas pressure. In high fire does pressure drop below the minimum on the rating plate?

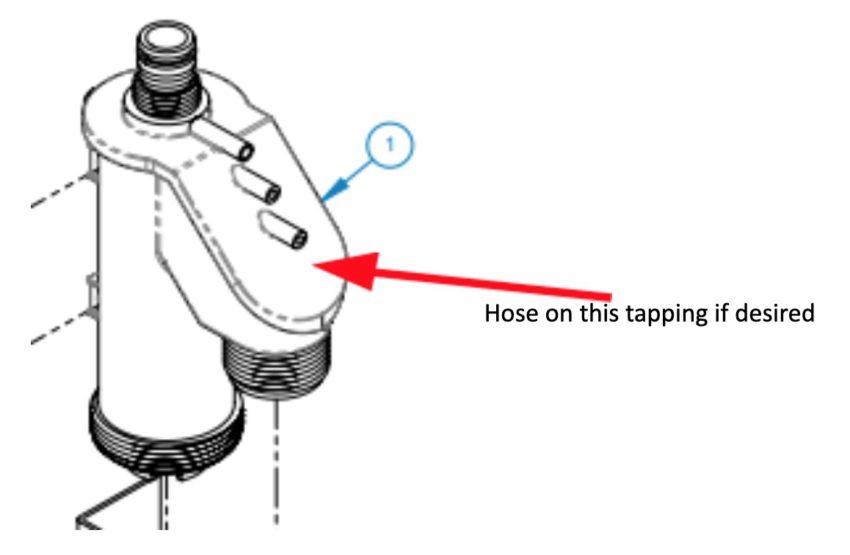

Leave wire disconnected and protect the wire ends from touching any metal surfaces. Use electrical tape or cut ends off and wire nuts as protection. The lower small hole on the right side of the trap is an overflow. If you want to put a hose on the tapping and drain as a back-up drain. If water drains from the hose the primary drain requires cleaning.

Disconnect the ignition wire from the ignitor and control. Meter the ignition cable for ohms. Are the ohms above 1000 Ohms?

Adjust the gas pressure to minimum gas pressures on the boiler label or higher not to exceed 14″ w.c. Normal natural gas pressures are 6″ w.c. to 8″ w.c. Lap normal gas pressures are 12.5″ w.c. to 13″ w.c.

Check the flame signal display. You will find this in the “Status” menu. Press status and scroll right until you see “Boiler status”. Doing start-up within about 4 seconds the flame Signal should be above 3 Micro-amps. Are Micro-amps high enough?

There is an orange wire between the Sage control and the condensate trap. The orange wire has a male & female spade connector about half way between the control and trap. Unplug the wires and fire the boiler. Did the boiler stay running?

Disassemble the gas train and view/clean inducer fan blades and swirl plate. Are the swirl plate and/ or fan blades deteriorated?

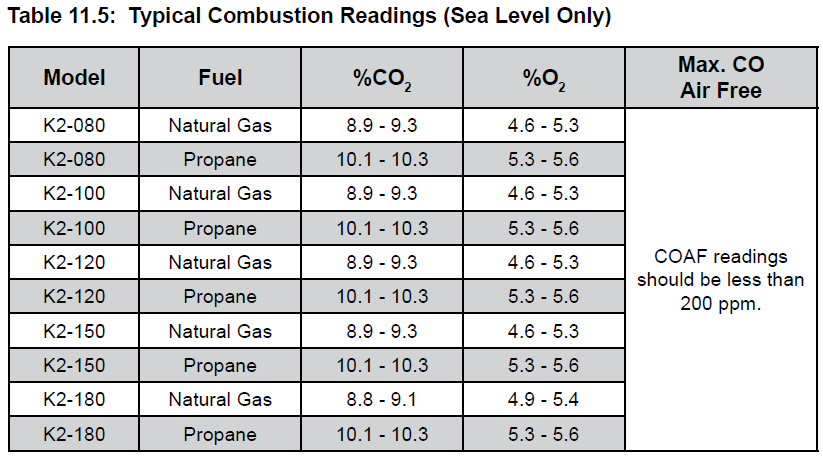

Connect your combustion analyzer to the vent connector by removing the test port cap. Lock the boiler in high fire and adjust the “02” and “CO” per the I&O manual. When complete turn boiler off and re-start.

See O2 Settings

Return the screw back 1 full turn clock-wise

Inspect/clean the burner tube.

Please contact Technical Support to resolve this issue.

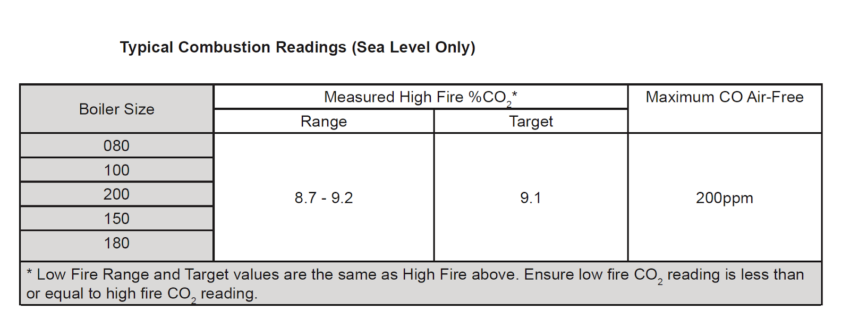

PHTNM Settings for Natural Gas

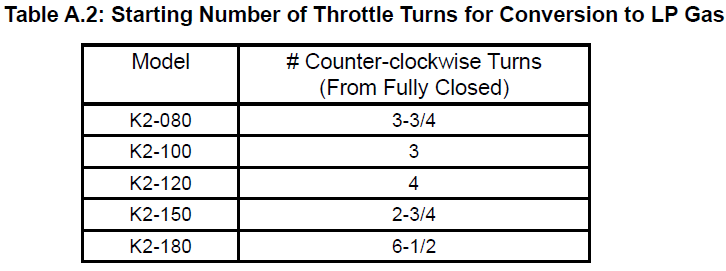

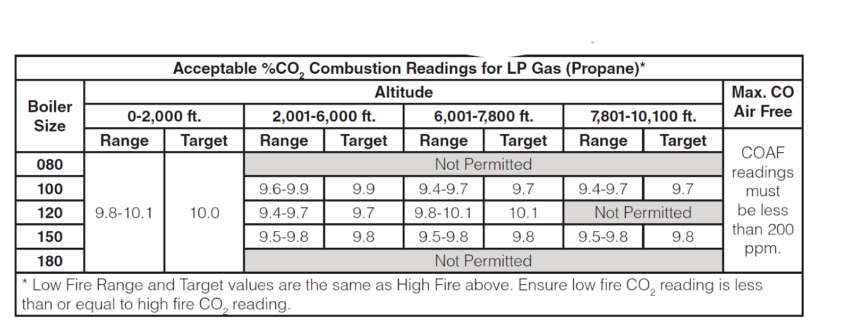

K2-FT O2 Settings for LP Gas

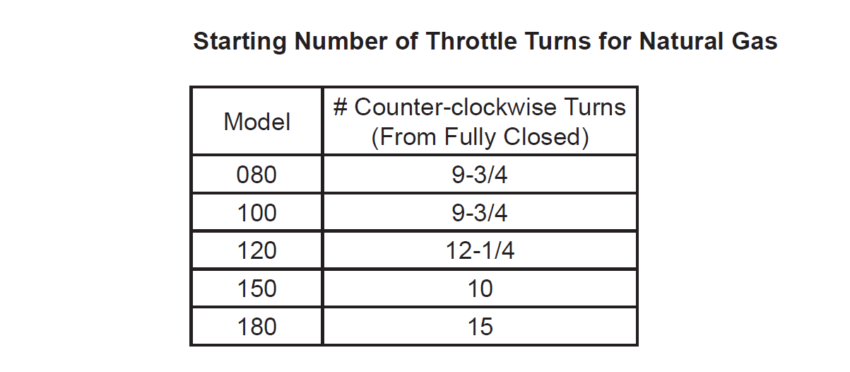

PHNTM Throttle screw adjustment from full closed Natural Gas

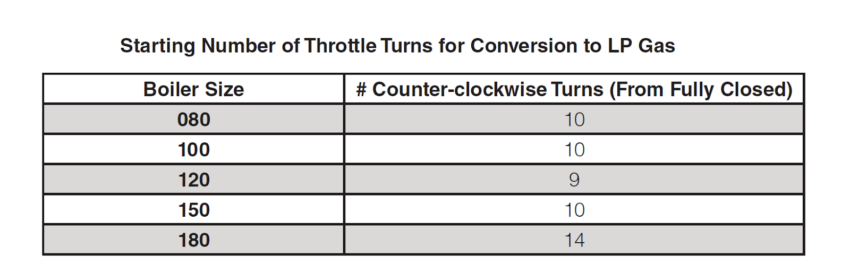

PHNTM Throttle screw adjustment from full closed LP Gas

K2-WT Natural & LP